News

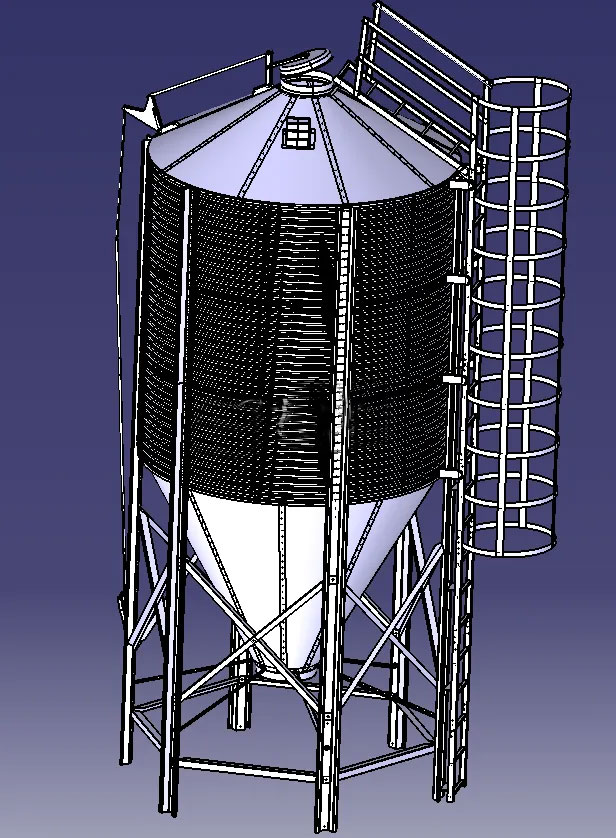

The feed tower is also what we call the feed storage tower, which is a storage device suitable for large and medium-sized farms. The feeding device is equipped at its outlet and has the function of regularly feeding feed into the barn. Our common silo is composed of the main body of the silo, the flip cover of the silo, the ladder and the column. There are see-through holes on the cone at the lower part of the silo, so the height of the feed in the silo can be observed.

The feed tower is mainly used to store dry powder or granular compound feed. There are many types materials for the feed tower, such as galvanized material feed tower, carbon steel feed tower, glass fiber reinforced plastic feed tower and so on.

The feed tower is designed in cylindrical and conical shapes, with a wider top and a narrower bottom, which can solve the problem of stable feeding and avoid clogging. There are also some ventilation holes on the side of the feed tower, which can remove various gases and help us with our usual cleaning work. Feed towers are usually smaller in diameter and higher in height. When the moisture content in the feed exceeds 13% or the storage time exceeds 2 days, the phenomenon of "arching" easily occurs in the feed tower, making it difficult for the feed to be discharged. Therefore, an arch-breaking device needs to be installed, so everyone must pay attention to it.

The feed tower also provides an automatic feeding device that is powerful and can reasonably match the feed. Not only that, but the feed tower also has a water storage function. When used, the feed is poured into the water storage device, so that our feed and water are reasonably mixed, and then sent to the pig house by the feeder, which reduces our use of manpower and makes our breeding work more convenient. The feed tower is also applied in poultry farms. Phoenix Breeding Equipment provides a complete set of automatic feeding equipment. Welcome to consult us!

The disadvantage of using a feed tower

1. Excessive temperature in the feed tower in summer

At present, the feed towers used in pig farms are made of galvanized sheet or glass fiber-reinforced plastic, the temperature in the feed towers can reach 60°C or even higher in summer, and the quality of vitamins in the feed is greatly affected. In addition, large temperature differences between day and night in summer can lead to water droplets and feed mold.

2. Water seepage in the feed tower in rainy days

The fastening bolts at the interface of the feed tower are not well sealed, or the quality of the sealant is not up to standard. After rain, there will be signs of water leaks in the feed tower. If the water content in the column is high, the feed tends to stick to the inner walls and then cakes and molds.

Solution

Some farms apply heat-reflective paint on the outside of the feed tower to reduce the temperature inside the tower, but it cannot solve the problem of water leakage on rainy days. Now, many farms build a shed above the feed tower, which is sprayed with a heat-reflective paint, which can effectively isolate the feed tower from the ultraviolet rays of direct sunlight, effectively prevent the deterioration of feed nutrients, and also prevent rainwater from entering the tower and causing the feed to mold.

The safety performance of the feeding tower is very important. We must ensure the safety of the personnel and the quality of the feed at the same time. If everyone does not master the correct method of using the feeding tower, it is difficult to have both. Then I will introduce to you how to use the feed tower correctly.

Operation steps for the use of the feed tower

1.Fill the silo with feed, then start the feeding motor, manually pour the feed into the hopper, and then the motor drives the screw to suck the feed into the silo, and the position of the feed in the silo is indicated by the "Silo Full Alarm" and "Silo Insufficient Alarm" on the control box. When there is insufficient feed in the silo, the "Silo Insufficient Alarm" indicator light will flash and an alarm will sound to remind workers to add the feed. When the silo is full, the 'Silo Full Alert' light is always on to remind you to stop adding the feed to the silo.

2.Press the "Manual/Automatic Mode" button, the red indicator light will be on, the machine will enter the manual mode, and the sensor will detect the trough signal and stop running.

How to observe the amount of feed in the feed tower

The feed content in the silo can be observed using the following 3 methods:

1. Judge the feed content in the silo by reading the weighing instrument installed under the hopper.

2. Fix one side of the rope, lift the heavy object to the other side through the pulley, tie a rope under the heavy object, and judge the feeding amount by pulling the rope to drive the heavy object to hit the material tower.

3. Lift the side ladder, open the box cover, and then observe the feeding amount with the naked eye.

View More information about chicken farm

VIEW our Youtube More breeding equipment video

Phoenix Breeding Equipment: 19+ years of breeding equipment production and export experience. As a result of our high-quality products and outstanding customer service, we have gained a global sales network reaching Europe, North America, Southeast Asia, Africa, South America, etc. Successfully in use on both family-owned farms and large farm complexes. Providing individual and automatic equipment to feed your livestock: chicken drinking line, chicken feeding line, poultry drinker and feeder, exhaust/ventilation fans, Egg Incubator, and so on breeding equipment.

CONTACT US

Phone:+86 19061974162

Email: sales@goldphoenixa.com

Pulished on May. 09, 2025

Pulished on Apr. 18, 2025