News

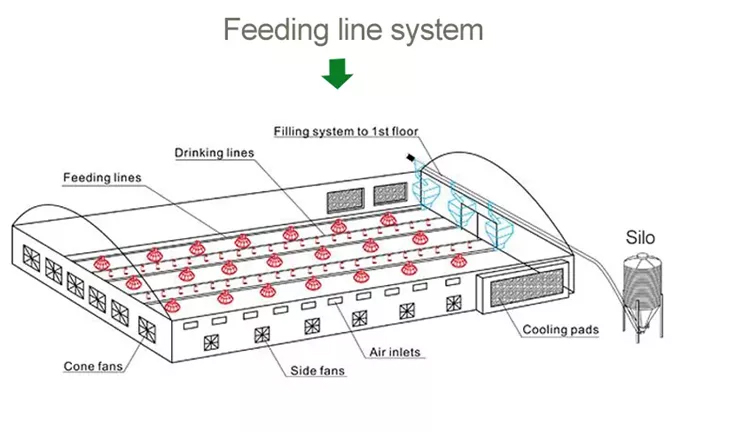

The automatic feeding line system for chicken farming is the preferred feeding system for modern large-scale chicken farms. There are many kinds of feeding line systems on the market now, but their working principles and system equipment configuration are roughly the same. Of course, the feeding line systems are quite different in terms of materials and the prices of accessories. Because the automatic chicken feeding line system is a system composed of many kinds of components that work together, good accessories can be well coordinated, with few problems and good quality, and the operation and maintenance are relatively simple. At the same time, the automatic chicken feed line system is suitable for many small chicken farms because of its simple structure and simple assembly.

The automatic feeding line system for chicken farming is the preferred feeding system for modern large-scale chicken farms. There are many kinds of feeding line systems on the market now, but their working principles and system equipment configuration are roughly the same. Of course, the feeding line systems are quite different in terms of materials and the prices of accessories. Because the automatic chicken feeding line system is a system composed of many kinds of components that work together, good accessories can be well coordinated, with few problems and good quality, and the operation and maintenance are relatively simple. At the same time, the automatic chicken feed line system is suitable for many small chicken farms because of its simple structure and simple assembly.

At present, the feed line commonly used by poultry farmers is also called the pan feed line in the breeding industry. The automatic chicken feeding line is mainly suitable for feeding broiler chickens, commercial chickens and finished chickens. It has the characteristics of a high degree of automation and feeding control. It is mainly composed of a feed tower, feeding pans, conveying pipe, auger, motor and feed level sensor. The feeding pan on each feeding line is generally divided into 16 grids, which can supply 50-70 chickens with a normal diet, and the feed is evenly distributed. It can effectively reduce the work intensity of chicken farmers, save breeding costs, and save time and effort.

Working principle of the automatic chicken feeding line

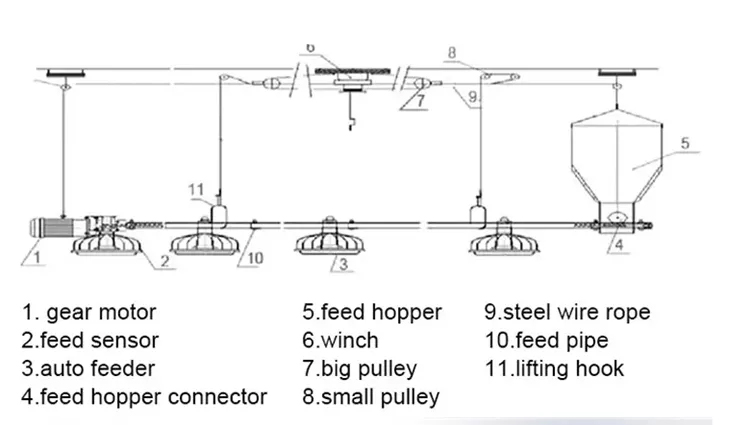

The main working principle of the automatic chicken feed line system is to drive the spiral feed tube to rotate through the transmission shaft of the drive system, so as to uniformly transfer the feed to each feeding pan. The system will judge whether there is feed in the front-end feed box, if the feed box is empty, control the motor to rotate; at the same time, a feed level sensor is installed at the end of the feeding line to detect whether the feeding line has been filled with feed, if it is full, control the motor to stop rotating, if not, control the motor to continue to rotate, and the whole feeding process achieves automatic control. After using the feeding line, the farmer only needs to pour the feed into the front-end feed box, and then feeding is automatically completed by the system, and the feeding process is quite easy. Not only reduces the trouble of artificial feeding but also reduces the slow growth of chickens caused by uneven artificial feeding.

Of course, it would be even better if it is matched with an automated drinking water line for chicken raising. Chicken farmers know that the water line and the feeding line are used together, which can not only achieve the ideal breeding effect, make more money, but also reduce a lot of labor force.

As long as the mouth of the chick touches the drinking nipple, no matter the front or the side, the nipple drinker will be opened. Therefore, it is very easy for the chicks to find drinking water, thereby reducing the water consumption of day-old chickens. Red drinkers are very easy to spot by chicks. In order to keep the forage dry, it is usually necessary to configure a drip cup.

Equipment configuration of automatic chicken feeding line

The quality of the automated chicken feed line system depends on the quality and coordination of the various accessories within the system. At present, the feeding line system used in many chicken farms will have two systems: the main feeding line and the auxiliary feeding line. The capabilities and specifications of each of the two systems vary.

1. Main feeding line system

It is composed of a feed tower, feed conveying pipe, auger, motor and feed level sensor. Its main function is to transport the feed in the feed tower to the hopper of the auxiliary feeding line, and there is a feed level sensor to automatically control the conveying switch of the motor to achieve the purpose of automatic feeding.

2. Auxiliary feeding line system

It consists of a hopper, a feeding pipe, an auger, a feeding pan, a suspension lifting device, a motor and a feed level sensor. Its main function is to transport the feed in the hopper to each feeding pan to ensure the eating of the broilers, and the feed level sensor will automatically control the opening and closing of the motor to achieve the purpose of automatic feeding.

Maintenance of automatic chicken feeding line

1. Regularly check the straightness of the feeding line, and check whether the screws and nuts are loose.

2. Regularly check the sealing condition of the electrical cabinet, wipe the outside of the control cabinet with a dry rag, and keep the control cabinet clean. Regularly check whether the wiring inside the control cabinet is secure.

3. Protect the motor with a textile bag or a feed bucket, and let the motor enter the water or the chicken jumps on the motor to pull the manure.

4. When flushing, raise the feeding line to the height, disassemble the bayonet between the feeding pan and the grille, let the feeding pan hang on the rotating pin of the grille, and use a high-pressure water gun to wash it. When washing, be sure to wrap the motor with waterproof plastic, to prevent water from entering the junction box.

5. Empty the feed from the spring feeding system as soon as the house is emptied before the system is cleaned.

6. Each batch of chickens should inject lubricating oil into the lifting winch once. Special attention: do not inject lubricating oil into the friction plate.

View More information about chicken farm.

VIEW our Youtube More breeding equipment video

Phoenix Breeding Equipment: 19+ years of breeding equipment production and export experience. As a result of our high-quality products and outstanding customer service, we have gained a global sales network reaching Europe, North America, Southeast Asia, Africa, South America, etc. Successfully in use on both family-owned farms and large farm complexes. Providing individual and automatic equipment to feed your livestock: chicken drinking line, chicken feeding line, poultry drinker and feeder, exhaust/ventilation fans, Egg Incubator, and so on breeding equipment.

CONTACT US

Phone:+86 19061974162

Email: sales@goldphoenixa.com

Pulished on Apr. 18, 2025